The bill climbs quickly with barely two disposable masks per day and per person, 400 tonnes of plastic waste is produced daily in France and which is found everywhere in nature, from the sidewalks to the bottom of the ocean.

The solution is to recycle this waste to limit its environmental impact. This is the choice that certain municipalities have made, such as that of Meudon in the Paris region.

Mask collection in Meudon

Masks on all faces, in the street, at school, in business … An accessory that has become commonplace, but which, after 4 hours of use, too often ends up in the trash or worse on the sidewalks. In Meudon, there is an alternative with twenty-five dedicated collection bins.

Every Tuesday, Stéphane Christin, employee of the ANRH association, makes his rounds: “I do the 25 points one after the other, at each point, I remove the bag, put another one back and I label the bag”.

5,000 masks collected per week

At the town hall, in schools, in markets, up to 5,000 used masks collected each week. Meudon embarked on the adventure at the end of January, a first in Ile-de-France.

Florence de Pampelonne, environmental assistant / Meudon (92): “When we saw the consequences of the pandemic with an incalculable number of masks used by users, we said to ourselves that something had to be done. Because you have to know that a mask thrown into nature takes 450 years to deteriorate, it is a major pollution that we will have to face, one more “.

100% French recycling

Avoid polluting but above all give this waste a new life. This collection is only the first step in a 100% French recycling process. It is in a factory in Châtellerault, that the masks will be transformed.

The first step is grinding. The entire mask, including the elastic band, is reduced to crumbs… all of which is subjected to UV-C rays for thirty seconds.

Masks transformed into geometry kits

Olivier Civil, co-founder of Plaxtil / Châtellerault (86): “We find the collection that comes from Meudon, a week of masks from Meudon. They have already been quarantined for seven days and they have been unscrewed, we have removed the metal bar, we behind us we transform them. We decontaminate in depth, there we are sure that there is no more trace of anything, in depth because we recycle all the material “.

From this decontaminated shred, the plant uses a patented and secret process to produce plastic granules, which in turn are molded into geometry kits, intended for schoolchildren in Meudon. A recycling from A to Z that the company had originally developed for ready-to-wear clothing.

Pollution is no longer inevitable

Olivier Civil, co-founder of Plaxtil / Châtellerault (86): “When the masks arrived, we said to ourselves it’s textile too, synthetic textile since it’s mostly polypropylene so we have the ability to recycle them, it’s our know-how. that we developed our circular solution to show that the masks are not only intended to end up burnt or thrown in the street. This material can be used again, we can make objects which themselves are recyclable and fit into a virtuous circle “.

Today the factory recycles tens of thousands of masks every week, collected in around thirty cities across France. It is a booming sector and a first step in the management of waste linked to the pandemic.

Cherry tomatoes contaminated with salmonella: 92 sick and 1 dead

Cherry tomatoes contaminated with salmonella: 92 sick and 1 dead  A better coaching method can make a person grow

A better coaching method can make a person grow  What is the method to prevent diabetes in children?

What is the method to prevent diabetes in children?  What are the effective factors in causing stomach ulcers?

What are the effective factors in causing stomach ulcers?  Why do embarrassing memories seem to appear at night?

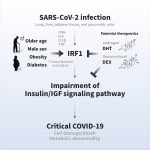

Why do embarrassing memories seem to appear at night?  The amazing link between SARS-CoV-2 infection and newly started diabetes

The amazing link between SARS-CoV-2 infection and newly started diabetes  WHO says monkey pox is not a global emergency right now

WHO says monkey pox is not a global emergency right now  Single cell RNA sequencing uncovers new mechanisms of heart disease

Single cell RNA sequencing uncovers new mechanisms of heart disease  Hepatitis of unknown origin: 3 new deaths and 228 cases worldwide

Hepatitis of unknown origin: 3 new deaths and 228 cases worldwide